Product Category

- Contact Us

Tel:

Tel: 0086-577-61726373

Fax:

Fax: 0086-577-61712103

E-mail:

E-mail:

Address:

Address: No.88 Liuqing North Road,Liushi Town,Yueqing City,Zhejiang Province,China

News

You are here: Home » News

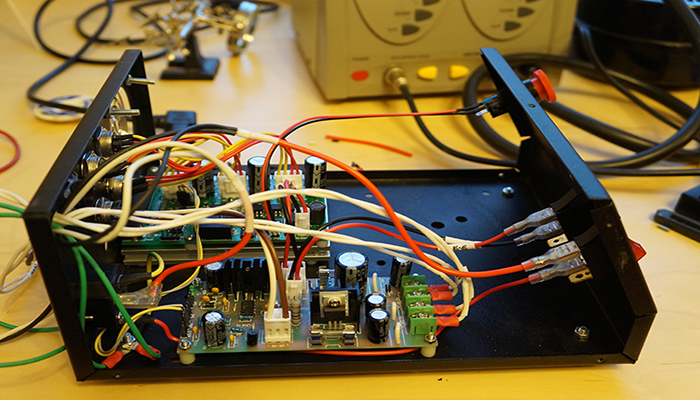

How to Wire a Power Supply?

Visit: 8179 Date: 2015-11-24

In order to improve the efficiency, people developed a switching regulated power supply,more than 85% efficiency, wide voltage range, the characteristics of high voltage stabilizing accuracy and without the use of power transformers. Because of this reason, switch power supply has been widely used in various kinds of electronic equipment.

Gechy Electric Co.,Ltd have been asked many times about PCBs for power supplies amplifiers. I do not recommend using a printed board for a number of reasons, and these are as follows ...

Limited range of capacitor values:

When the constraints of a PCB are imposed, the capacitors you choose must be the same physical size as those the board can accommodate. This restriction is so great (IMO) that this precludes the use of a board for almost any DIY power amplifier project.

Electrical Characteristics:

The normal copper thickness on a printed board is not really sufficient to ensure that there is minimal resistance, so there is a greater likelihood of hum (or buzz) and efficiency may be marginally reduced. In contrast, hard wiring can be as thick as the constructor likes (although it is still necessary to be able to solder to it and the capacitor terminals).

Physical layout:

A printed board limits the flexibility to mount capacitors in the most convenient place. This is probably one of the most compelling reasons to use hard wiring, since multiple capacitors may be best arranged in a row or a block, depending on the internal construction of the chassis mounted components (e.g. transformer, heatsinks, PCBs, etc.).

Other components:

Gechy Electric Co.,Ltd have been asked many times about PCBs for power supplies amplifiers. I do not recommend using a printed board for a number of reasons, and these are as follows ...

Limited range of capacitor values:

When the constraints of a PCB are imposed, the capacitors you choose must be the same physical size as those the board can accommodate. This restriction is so great (IMO) that this precludes the use of a board for almost any DIY power amplifier project.

Electrical Characteristics:

The normal copper thickness on a printed board is not really sufficient to ensure that there is minimal resistance, so there is a greater likelihood of hum (or buzz) and efficiency may be marginally reduced. In contrast, hard wiring can be as thick as the constructor likes (although it is still necessary to be able to solder to it and the capacitor terminals).

Physical layout:

A printed board limits the flexibility to mount capacitors in the most convenient place. This is probably one of the most compelling reasons to use hard wiring, since multiple capacitors may be best arranged in a row or a block, depending on the internal construction of the chassis mounted components (e.g. transformer, heatsinks, PCBs, etc.).

Other components:

A PCB is less than ideal (to put it mildly) for mounting a bridge rectifier, and doubly so if a 35A chassis mount bridge is used. These need to be on a metal panel to obtain heatsinking, and it is very hard to achieve this when a PCB is used.

Previous:

Next:Classification of regulated switching power supply

Next:Classification of regulated switching power supply

English

English Pусский

Pусский